Welcome to the Golden Technologies Lift Chair Repair Manual. This guide provides comprehensive instructions for troubleshooting, maintaining, and repairing various lift chair models, ensuring optimal functionality and longevity.

1.1 Purpose of the Manual

This manual is designed to assist users, caregivers, and technicians in troubleshooting, maintaining, and repairing Golden Technologies lift chairs. It provides detailed procedures for identifying and resolving common issues, ensuring safe and effective repairs. The guide covers models such as 3-position, 2-position, MaxiComfort, and 500-lb. lift chairs, offering step-by-step instructions for replacing parts and performing routine maintenance. By following this manual, users can extend the lifespan of their lift chairs and ensure optimal performance, while adhering to safety standards and manufacturer recommendations.

1.2 Scope of the Manual

The manual encompasses troubleshooting, maintenance, and repair procedures for Golden Technologies lift chairs, including 3-position, 2-position, MaxiComfort, and 500-lb. models. It details systematic fault tracing, replacement procedures, and exploded part views. The guide also covers essential safety protocols, tool requirements, and component understanding. Additionally, it provides maintenance tips, warranty information, and contact details for support. This comprehensive resource ensures users can address common issues effectively, promoting longevity and functionality of their lift chairs while adhering to manufacturer guidelines.

1.3 Target Audience

This manual is designed for authorized service providers, repair technicians, and maintenance personnel who need detailed guidance on troubleshooting and repairing Golden Technologies lift chairs. It is also useful for caregivers and end-users seeking to understand basic maintenance and operation. The content is tailored for individuals with technical skills, ensuring they can perform repairs safely and effectively. The manual assumes familiarity with basic tools and mechanical concepts, making it accessible to both professionals and knowledgeable enthusiasts. Its comprehensive approach ensures that all necessary information is provided to maintain and repair lift chairs efficiently.

Safety Precautions for Repair

Disconnect power before starting repairs. Use proper tools and protective equipment. Avoid mechanical hazards and follow electrical safety guidelines to ensure a safe repair process.

2.1 General Safety Guidelines

Always disconnect the power supply before starting any repair. Wear protective gear like gloves and safety glasses. Ensure the chair is stable and on a level surface. Avoid overreaching or using improper tools, as this may cause injury or further damage. Regularly inspect components for wear or damage. Never attempt repairs while the chair is in use or occupied. Follow all manufacturer instructions and guidelines. Keep loose clothing and long hair tied back to avoid entanglement. Periodically check for any blockages or obstructions in moving parts. Adhere to these precautions to ensure a safe and effective repair process;

2.2 Electrical Safety Considerations

Always unplug the lift chair from the power source before performing any electrical repairs. Verify that the power is off using a voltage tester. Avoid touching electrical components with wet hands or while standing on a conductive surface. Never bypass or disable safety features like circuit breakers or fuses. Use only authorized replacement parts to maintain electrical integrity. Insulate any exposed wires or terminals to prevent accidental contact. Ensure all connections are secure and properly insulated after repairs. Consult a professional if unsure about any electrical procedure. Follow these guidelines to prevent electrical shocks or system malfunctions during repairs.

2.3 Mechanical Safety Precautions

Always ensure the lift chair is stable and secure before performing mechanical repairs. Wear protective gloves and safety glasses to prevent injury from sharp edges or moving parts. Use proper tools to avoid damaging components or causing accidental movement. Never attempt to lift or move heavy parts without assistance. Keep loose clothing and long hair tied back to avoid entanglement with moving mechanisms. Ensure all mechanical components are properly secured before testing the chair. Avoid overexertion when handling parts, and follow proper lifting techniques to prevent personal injury. These precautions will help ensure a safe repair process.

Tools and Equipment Required

Essential tools include screwdrivers, Allen wrenches, pliers, and multimeters. Specialized equipment such as hydraulic lifts, diagnostic tools, and exploded diagrams are also necessary for repairs.

3.1 Essential Tools for Repair

The essential tools required for repairing Golden Technologies lift chairs include screwdrivers (Phillips and flathead), Allen wrenches, pliers, and a multimeter for diagnosing electrical issues. A socket set and adjustable wrench are useful for mechanical components. Additionally, a torque wrench ensures proper tightening of bolts, while a work light illuminates hard-to-see areas. Safety gloves and goggles protect during repairs. These tools are fundamental for disassembling, inspecting, and reassembling lift chair components effectively. Always refer to the specific model’s manual for tool specifications to ensure compatibility and safety.

3.2 Specialized Equipment Needed

Specialized equipment for repairing Golden Technologies lift chairs includes diagnostic tools like a programmer for R-Series or PG VR2 controllers and a battery tester for power systems. A hydraulic pressure gauge may be needed for chairs with hydraulic lift mechanisms. Additionally, access to service guides, exploded view diagrams, and specific torque specifications is crucial. Advanced multimeters for detailed electrical troubleshooting and custom wrenches for specific bolts may also be required. These tools enable precise diagnostics and repairs, ensuring the chair operates safely and efficiently. Always refer to the model-specific manual for exact equipment requirements.

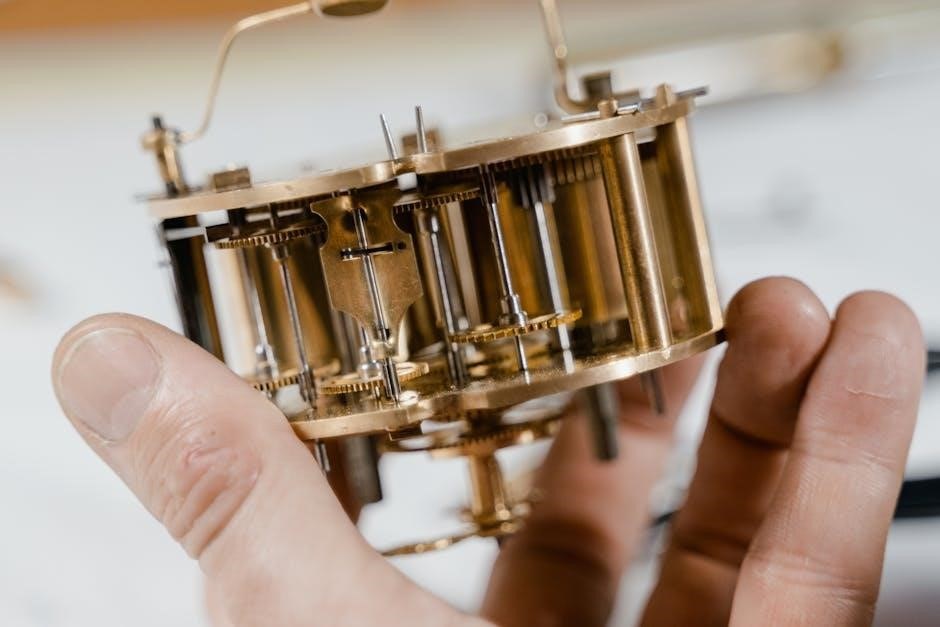

Understanding the Lift Chair Components

Golden Technologies lift chairs consist of key components such as the power supply, motor, lift mechanism, and control panel. Understanding these parts ensures effective troubleshooting and repair.

4.1 Power Supply and Motor System

The power supply converts AC power to DC for the motor, enabling smooth operation. The motor drives the lift and recline mechanisms, ensuring precise adjustments. Regular inspection of these components is crucial for maintaining functionality and preventing malfunctions. Proper maintenance includes checking connections and ensuring the motor operates quietly and efficiently. Any unusual noise or hesitation indicates a potential issue requiring immediate attention. Always refer to the manual for specific guidelines on handling the power supply and motor system to ensure safety and longevity of the lift chair.

4.2 Lift Mechanism and Actuators

The lift mechanism is responsible for raising and lowering the chair, utilizing a combination of mechanical and motorized components. Actuators play a critical role in controlling the chair’s vertical movement, ensuring smooth and precise adjustments. Proper lubrication and alignment of these parts are essential for maintaining optimal functionality. Regular inspection for wear or damage is recommended to prevent mechanical failure. If the lift mechanism becomes jerky or unresponsive, it may indicate worn actuators or motor issues, requiring immediate attention to ensure user safety and reliability. Always refer to the manual for specific maintenance guidelines.

4.3 Control Panel and Sensors

The control panel serves as the primary interface for operating the lift chair, managing functions like reclining, footrest adjustment, and lift mechanisms. Sensors integrated into the system monitor the chair’s position and movement, ensuring smooth transitions and preventing operational errors. Regular inspection of sensors is crucial to maintain accuracy and responsiveness. If the control panel fails to respond, check for loose connections or damaged sensors. Refer to the manual for troubleshooting steps or replacing faulty components. Proper maintenance of these elements ensures reliable performance and user safety, aligning with Golden Technologies’ quality standards for assistive devices.

4.4 Recline and Footrest Mechanisms

The recline and footrest mechanisms are essential for user comfort and functionality. These systems rely on precisely engineered gears and actuators to ensure smooth transitions between positions. Regular lubrication of moving parts is vital to maintain seamless operation. Inspect for wear or misalignment, as these can cause jams or uneven movement. Cleaning and proper alignment are key to longevity. Always refer to the manual’s exploded views for accurate disassembly and repair guidance. Proper care extends the lifespan of these mechanisms, ensuring optimal performance and user satisfaction.

Troubleshooting Common Issues

This section addresses frequent problems like motor failure, control panel unresponsiveness, and lift mechanism jams. Follow systematic steps to identify and resolve issues efficiently using this guide.

5.1 Motor Failure or Malfunction

Motor failure in Golden Technologies lift chairs can occur due to power supply issues, worn components, or control panel malfunctions. First, check the circuit breaker or fuse. Ensure the chair is properly plugged in and the outlet is functioning. If the motor still doesn’t operate, inspect for loose connections or damaged wiring. Consult the troubleshooting guide for specific error codes or unusual noises. Perform a diagnostic test using the control panel to isolate the issue. If the motor is faulty, refer to the repair procedures for replacement instructions. Always prioritize safety and disconnect power before attempting repairs. Regular maintenance can prevent such malfunctions.

5.2 Control Panel Not Responding

If the control panel of your Golden Technologies lift chair is unresponsive, start by checking the power supply. Ensure the chair is properly plugged into a functioning outlet. Verify that the circuit breaker or fuse hasn’t tripped. Next, inspect the wiring connections between the control panel and the motor system for damage or looseness. If the issue persists, the control panel or sensors may need replacement. Refer to the troubleshooting guide for specific error codes or symptoms. Always disconnect power before performing repairs. Consulting the manual or contacting Golden Technologies support can provide additional guidance for resolving this issue effectively.

5.3 Lift Mechanism Stuck or Jammed

If the lift mechanism is stuck or jammed, begin by powering off the chair and ensuring no obstructions block its movement. Inspect the lift mechanism for visible damage or misalignment. Check the gears and pistons for wear or debris accumulation. Lubricate moving parts if necessary, using silicone-based lubricant. If the issue persists, consult the exploded views in the manual to identify and replace faulty components. Always disconnect power before attempting repairs. Contact Golden Technologies support if the problem remains unresolved after these steps.

Repair Procedures for Key Components

This section outlines step-by-step repair procedures for critical components, such as the power supply, lift mechanism, and control panel. Refer to exploded views for part identification and follow proper techniques to ensure safe and effective repairs.

6.1 Replacing the Power Supply Unit

To replace the power supply unit, first disconnect the lift chair from the electrical outlet to ensure safety. Locate the power supply unit, typically found in the base of the chair. Remove any components blocking access, such as the controller or cover panels. Detach the electrical connectors and mounting bolts securing the unit. Install the new power supply by reversing the removal steps, ensuring all connections are secure. Test the chair to confirm proper functionality. If unsure, consult the manual or contact Golden Technologies support for assistance.

6.2 Fixing the Lift Mechanism

To fix the lift mechanism, start by identifying the source of the issue. If the mechanism is jammed or stuck, inspect for obstructions and ensure the motor is functioning properly. If the motor is faulty, replace it by disconnecting the electrical connectors and removing the mounting bolts. Install the new motor, ensuring all connections are secure. For gear-related problems, access the gear assembly, remove the faulty gears, and replace them with compatible parts. Refer to the exploded diagrams in the manual for precise guidance. After repairs, test the lift mechanism to ensure smooth operation. If issues persist, consult the manual or contact Golden Technologies support for further assistance.

6.3 Recliner and Footrest Repair

For recliner and footrest repairs, inspect the mechanisms for wear or damage. If the recliner is not adjusting properly, check the motor and gear assembly. Lubricate moving parts if stiffness is detected; If the footrest does not extend or retract, ensure the linkage is aligned and free from obstructions. Replace any damaged components, such as faulty springs or gears, using the exploded diagrams provided in the manual. After repairs, test the recliner and footrest to ensure smooth operation. If issues persist, consult the troubleshooting guide or contact Golden Technologies support for further assistance.

Maintenance Tips for Longevity

- Regularly inspect and lubricate moving parts to ensure smooth operation.

- Keep the chair on a firm, level surface to prevent imbalance.

- Clean and maintain the battery and power supply for optimal performance.

- Follow the recommended maintenance schedule outlined in the manual.

These practices will help extend the lifespan of your Golden Technologies lift chair.

7.1 Regular Inspection Schedule

Regular inspections are crucial for maintaining your Golden Technologies lift chair. Schedule monthly checks of the power supply, motor, and control panel for signs of wear. Every 3-6 months, inspect the lift mechanism, actuators, and footrest for proper alignment and function. Annually, examine the recline mechanism and ensure all bolts and screws are tightened. Additionally, check the battery terminals for corrosion and clean them if necessary. Lubricate moving parts as recommended to prevent friction and extend component life. Always refer to the manual for specific inspection guidelines tailored to your model.

7.2 Lubrication and Cleaning Practices

Regular lubrication and cleaning are essential for maintaining your Golden Technologies lift chair. Apply silicone-based lubricant to moving parts like hinges and gears every 6 months to ensure smooth operation. Avoid over-lubrication to prevent dust accumulation. For cleaning, use a soft, dry cloth to wipe down metal components. Dampen the cloth slightly for tougher stains, but avoid harsh chemicals. Clean the control panel with a mild detergent and water solution, ensuring no moisture seeps into electrical components. Regular cleaning prevents wear and extends the chair’s lifespan, keeping it functional and hygienic for years.

7.3 Battery Maintenance Guidelines

Proper battery maintenance ensures reliable performance of your Golden Technologies lift chair. Check battery terminals monthly for corrosion and clean them with a wire brush if necessary. Charge the battery regularly, especially during extended use or power outages. Use only the manufacturer-recommended charger to avoid damage. Replace batteries every 2-3 years or when capacity significantly decreases. Store unused batteries in a cool, dry place to prolong life. Always follow the manual’s guidelines for battery care to maintain optimal functionality and safety of your lift chair.

Warranty and Support Information

Golden Technologies offers comprehensive warranty coverage for lift chair components, including the lift mechanism and frame. Contact their support team at 800-677-6293 or visit their website for assistance.

8.1 Warranty Coverage Details

Golden Technologies provides a limited lifetime warranty for the lift mechanism, chair frame, and recline system, ensuring durability and performance. The warranty covers repairs or replacements at Golden’s discretion, focusing on structural integrity and core components. This warranty applies to the original consumer and is non-transferable. For specific terms and conditions, refer to the product manual or contact customer support. Regular maintenance, as outlined in the manual, is essential to uphold warranty validity and ensure optimal chair functionality.

8.2 Contacting Golden Technologies Support

For assistance or inquiries, contact Golden Technologies support at 800-677-6293. Their team is available to address repair questions, warranty issues, or technical concerns. Visit their official website or explore resources like service guides and manuals for additional support. For online purchases, ensure authorization to sell Golden products. Their customer service ensures comprehensive assistance, maintaining your lift chair’s performance and longevity with reliable solutions and expert guidance. Reach out to resolve any issues promptly and effectively.

This manual provides comprehensive guidance for repairing and maintaining Golden Technologies lift chairs, ensuring safety and longevity through detailed procedures and essential maintenance tips.

9.1 Summary of Key Repair Steps

This section summarizes the essential repair steps for Golden Technologies lift chairs. Start by diagnosing the issue using troubleshooting guides. Replace faulty components like motors or control panels as needed. Always follow safety protocols and manufacturer instructions. Regularly inspect and maintain parts, such as lubricating mechanisms and checking battery connections. Refer to exploded diagrams for part identification. Ensure all repairs align with warranty guidelines to avoid voiding coverage. Proper maintenance and timely repairs will extend the chair’s lifespan and ensure reliable operation for users. Adhere to safety precautions throughout the process to prevent accidents or further damage.

9.2 Final Safety Reminders

Always disconnect power before starting repairs. Use proper tools and follow manufacturer guidelines to avoid damage or injury. Ensure all components are securely tightened post-repair. Test the chair thoroughly before use to confirm functionality. Keep loose clothing and long hair tied back when operating. Avoid overloading the chair beyond its weight capacity. Store batteries in a cool, dry place and replace them periodically. Regularly inspect wires and connections for wear. If unsure about any step, consult a professional technician. Adhere to these safety reminders to ensure safe and effective repairs.